Products

« Category overview | Dedusting equipment

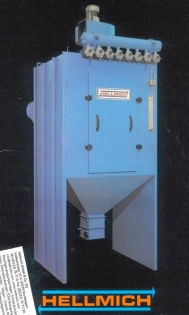

Dedusting system with cleaning of compressed air, 4000 mÂł/h, used -

SOLD OUT(Article number: 3110)

|

|||||||

| Manufacturer: | Hellmich | ||||||

|---|---|---|---|---|---|---|---|

| Type: | / | ||||||

| Year of construction: | 1982 | ||||||

| Description: | Filter surface: 33 m² Fan: MA 67/200 Air volume: 4000 m³/h Motor power: 4 kW In the deduster several filter bags are each combined into a group. These groups are cleaned one after the other. The cleaning takes place with compressed air surge via solenoid valves and turbo nozzles. The blast of compressed air causes a rapid pressure increase in the filter bags and results in a short-term reversal of the air flows through the filter cloth. The dust cake dissolves and falls down. By using the turbo nozzles, the compressed air consumption is low. The cleaning is triggered by an adjustable differential pressure switch as soon as the dust-loaded filter bags have reached the preselected resistance. This cleaning is economical because it is demand-based. The required amount of compressed air depends on the type of dust and the amount of dust. The duration of the cleaning impulses can be set (usually about 0.1 sec.). Attachment of suction hoses with steel band snap ring and double chafer. Assembly and disassembly without tools feasible. Condition: used |

||||||

| Quantity: | 1 Pc. | ||||||

| Data in accordance with manufacturer | |||||||

|

|||||||